Rain coat

Product configuration

It is made with the reaction between special rubber and synthetic resin and has strong penetration, water resistance, and adhesion. It is used as basic waterproof solvent (1st waterproof) having excellent adhesion on wet surfaces in case of dust prevention on steel and water resistance on concrete.

Product characteristics

– It has strong adhesion, which does not require primer process.

– It uses 2-time construction for minimizing process.

– It has an excellent elongate rate to thin membrane (50um), which can effectively respond to cracks.

– Tacking (becoming sticky) does not occur after construction, so contamination does not occur.

– With its water repellent effect, cleaning can be done automatically after raining.

– There is little to no yellowing.

– Elongation rate is excellent.(General water paint does not have excellent elongation rate.)

– Viscosity is approx. 2,000CPS ± 100.

Product characteristics

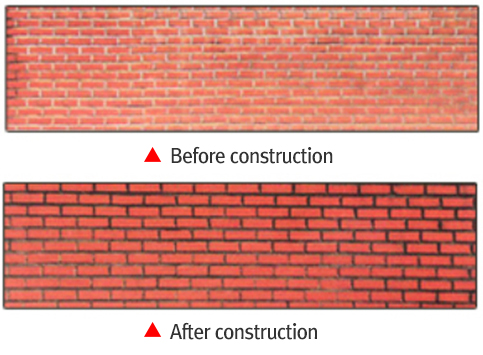

| Rough surface (dryvit, brick) | Approx. 40 m² |

| General surface (plaster surface) | Approx. 70 m² |

| Smooth surface (tile) | Approx. 100 m² |

| Tools | roller, brush, spray |

How to use and caution

| How to use | – Painting condition is when the air temperature is 10–30℃ and relative humidity is 85% or less. – Mix the paint sufficiently before construction. – Pour 1 cup of water for 1st construction depending on the temperature. – Carry out 2nd construction without pouring water. * Aqueous paint can be used for mixing color. (basic color : semi-glossy white color) * Minimum amount for mixing color is at least 50 packs. (pastel color is possible) |

|---|---|

| caution | – Concrete surface should be sufficiently cured (4 weeks or more at 20℃), and apply paint when pH is 8–9 or less and moisture content is 8% or less. – Aqueous paint should be stored in indoor areas (at room temperature of 5℃ or higher) that can avoid direct light. – If surface processing is insufficient, it might lead to poor adhesion and detachment of membrane. – In case of exceeding recommended amount (within 10%) of diluent (water), it might lead to reduction in material property. – Primer (mixing) can be lifted with stronger adhesion compared to primer (mixing) process, so primer (mixing) process should be omitted. – Pour 3 cups of diluted water for painting 18kg of Champion on the membrane and carry out 1st and 2nd construction. – If primer (mixing) process has been carried out by mistake, carry out drying for 24 hours or more before construction. |