Consulting on quality of compressed air

Need for compressed air

Compressed air is the air that is compressed for use as power.

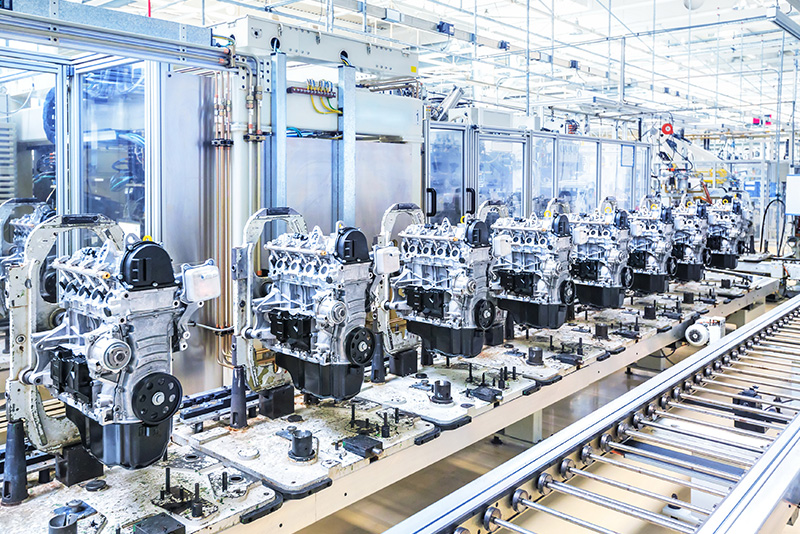

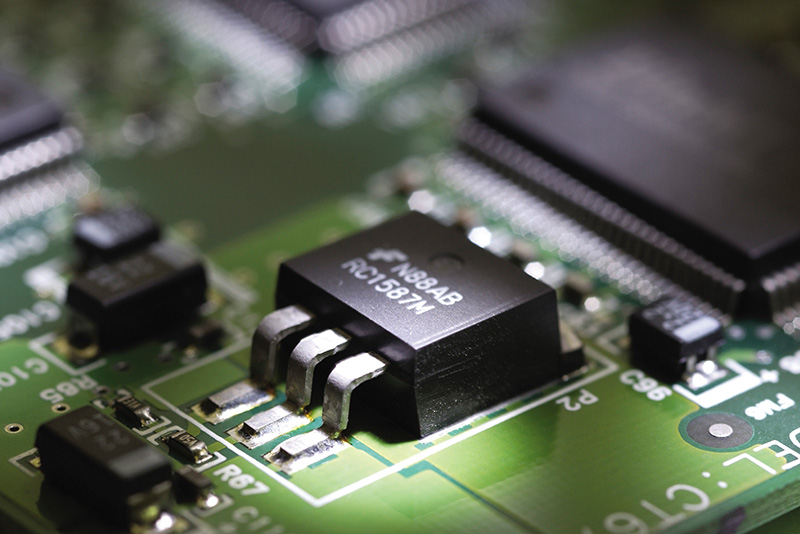

It is essential for plant operations in all industries around the world,

including vessels, electricity, electronics, semiconductors, petrochemicals, plants, machinery, engineering, food, and more.

Compressed air is also a source of energy for operating various machinery and equipment in industrial sites.

What happens if compressed air is used without being managed?

It can cause product defects, stops in production lines, and deterioration of quality.

- phenomenon of equipment stoppage

- Occurrence of product defect due to stains or marks

Various machinery

- Failure in normal operations

- Clogging phenomenon of valve or instrument

- phenomenon of equipment stoppage

- Increase in defective products due to contamination

- Product degeneration due to cross-contamination

- Extraordinary reactions caused by moisture

- Product degeneration due to cross-contamination

- Product decomposition and defects

- Unevenness and damage on painted surfaces

- Occurrence of painted surface that is not smooth

Quality factors of compressed air

01 Moisture

When air is compressed, the concentration of relative humidity increases as the volume decreases, resulting in a large amount of moisture.

Moisture is a major contaminant of compressed air systems and creates condensation where bacteria live.

Accordingly, there is a high risk of corrosion inside the pipe, which makes it very important to properly maintain the dew point.

02 Oil

If the air compressor uses lubricating oil, it is inevitable that oil is mixed in with the compressed air. Oil exists in a variety of forms.

The amount of oil contained in compressed air is quite difficult to guess, so it is best to check it directly.

03 Foreign Matter

There are about 140 million solid particles per 1㎥ of air in the atmosphere. Of these, 80% are less than 2㎛ in size.

If such air flows into the air compressor, the operating parts of the compressor may be damaged by the solid particles.

Therefore, a filter with a suitable filtration capacity and efficiency should be used.

It is difficult to identify moisture, oil, and foreign substances contained in the air with the naked eye

because the particles are very small.

JEONGWOO Flow directly measures the condition of compressed air used in the field

and diagnoses whether it complies with ISO standards for compressed air quality for each industry.

Below shows the quality standard for compressed air for representative industries, which was published by the ISO

(International Standardization Organization.)

Please contact us for any inquires and more information on other industries.

<Classes of Compressed Air Quality – 8583-1: 2010>

01 Moisture

| Class | Dew point under pressure (℃) |

| 0 | Contact us – Super dry air technology |

| 1 | ≤ -70℃ |

| 2 | ≤ -40℃ |

| 3 | ≤ -20℃ |

| 4 | ≤ +3℃ |

| 5 | ≤ +7℃ |

| 6 | ≤ +10℃ |

| Class | Concentration of liquid Cw(g/㎥) |

| 7 | Cw ≤ 0.5 |

| 8 | 0.5 < Cw ≤ 5 |

| 9 | 5 < Cw ≤ 10 |

| X | Cw > 10 |

02 Oil

| Class | Total concentration of oil (㎎/㎥) |

| (Liquid, aerosol + gas) | |

| 0 | Contact us – Super dry air technology |

| 1 | ≤ 0.01 |

| 2 | ≤ 0.1 |

| 3 | ≤ 1.0 |

| 4 | ≤ 5.0 |

| X | > 5.0 |

- Standard conditions 20 (℃) , 1 (barG) , 0 (%) Moisture

03 Foreign Matter

| Class | Maximum particle size per ㎥ d (㎛) | ||

| 0.1≤d≤0.5 | 0.5≤d≤1.0 | 1.0≤d≤5.0 | |

| 0 | Contact us – Super dry air technology | ||

| 1 | ≤ 20,000 | ≤ 400 | ≤ 10 |

| 2 | ≤ 400,000 | ≤6,000 | ≤ 100 |

| 3 | – | ≤ 90,000 | ≤ 1,000 |

| 4 | – | – | ≤ 10,000 |

| 5 | – | – | ≤ 100,000 |

| Class | Particulate concentration Cp(g/㎥) | ||

| 6 | 0 < Cp ≤ 5 | ||

| 7 | 5 < Cp ≤ 10 | ||

| X | Cp>10 | ||

01) Food (HACCP)

Compressed air that directly comes into contact with food

→ Moisture : Level 2 / Oil : Level 2 / particle concentration : Level 1

Compressed air that indirectly comes into contact with food

→ Moisture : Level 2 / Oil : Level 4 / particle concentration : Level 2

[Reference] Food & Beverage Grade Compressed Air Best Practice Guideline (U.K. Compressed Air Association)

02) Dentist

Moisture : Level 5

Oil : Level 1

Particulate : Level 3 or higher

[Reference] American Dental Association_Dental Compressed Air Quality Standard Compressed air diagnostics procedure of JEONGWOO Flow

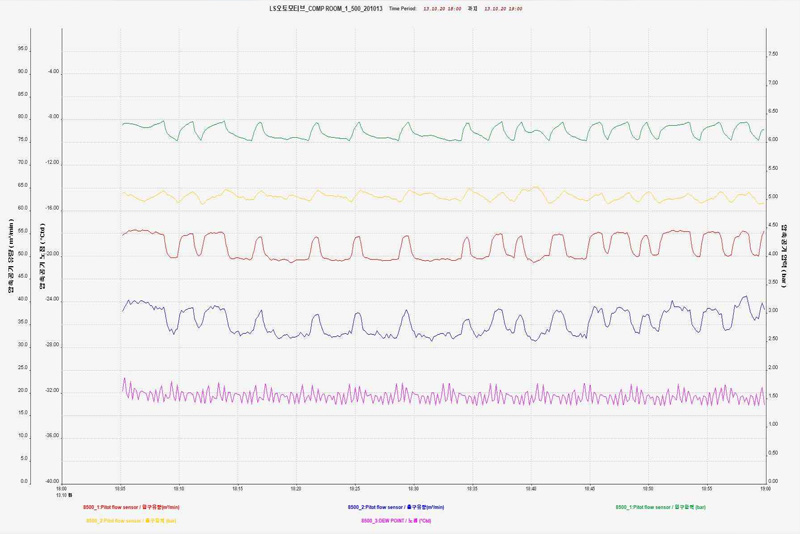

<Compressed air diagnostics procedure of JEONGWOO Flow>

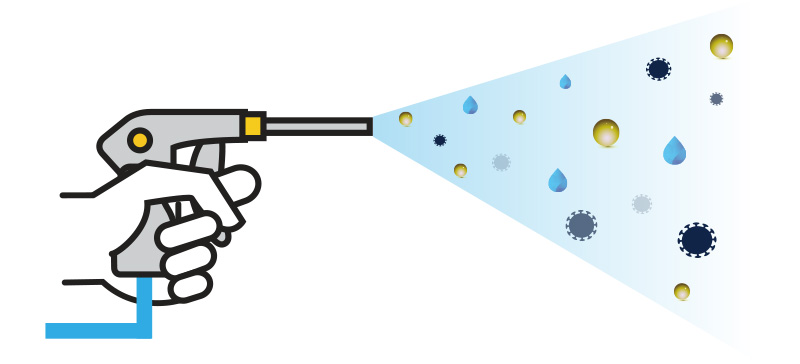

01 Compressed Air Measurement

Compressed air used in the field is sampled for measurement,

If it cannot be sampled, the method of drilling the existing pipe and branching

(drilling without stopping water supply) is used for sampling.

02 Compressed Air Quality Diagnosis

A measuring instrument is used to measure and diagnose quality factors (moisture, oil, foreign matter) of compressed air.

03 Diagnostics Report

A final diagnostic report is provided by calculating the measurement graph of the compressed

air system and annual consumption of energy,

Information on problems and solutions are provided as part of the free service.

| – Suitable Lubricant Recommendations | – Qualified Part(filters)Recommendations |

| – Information on Filter Replacement Time | – Proposal for a Monitoring System |