PCM PLUS SERIES

PCM PLUS SERIES

High temperature integrated type embedded with filter

Product configuration

Product characteristics

Phase changing dryer with differentiated technology

• PCM (phase changing material) is applied (application for patent rights)

• Refrigerant compressor ON/OFF control depending on the load of compressed air

High-temperature integrated product leading to energy reduction

• Plate type heat exchanger is applied on the stainless steel brazing embedded with PCM

• Energy reduction up to 99% with inexpensive energy cost

• Collection of initial investment cost in shortest time

Processing entrance temperature for up to 60℃

• Provide stable dehumidification performance

in high-temperature working environment

Upgrade in basic performance with installation of front / rear filter

• Front filter (3) – remove foreign substance and condensate water

• Rear filter (0.01) – remove high-efficiency oil, coalescing capability

• Simple product installation and maintenance

No Loss Drain

• Static volume sensor

• Zero air loss in case of discharge in condensate water

• Automatic conversion to timer mode when malfunction occurs

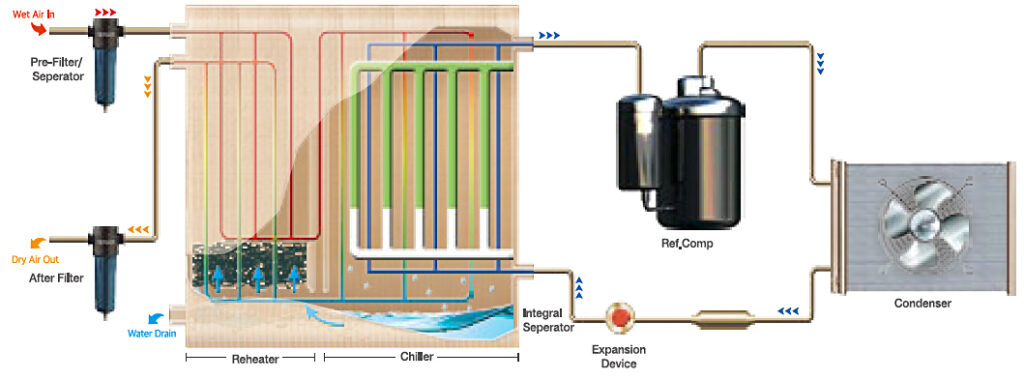

작동원리

phase-changing of PCM

- If cooling compressor and condenser fan are operated for coolant recirculation, coolant in the chiller freezes PCM.

- If the PCM becomes frozen, coolant compressor and condenser fan stop operation.

- While the coolant circulation is stopped, compressed air is continuously cooled and dehumidified by frozen PCM and the energy can be reduced with no consumption of electricity.

- With continuously flowing compressed air, PCM starts melting. When PCM is completely melted, freezing compressor and condenser fan start operation and PCM cooling is carried out.

Dehumidification of compressed air

- If high-temperature compressed air moves into dryer, condensate water and foreign substance are removed from front filter / separator.

- By exchanging heat with cool air in the exit, it goes through 1st cooling and moves to chiller following the path in the heat exchanger for cooling PCM and 2nd heat exchange..

- In this case, condensate water is separated from compressed air and separator at the bottom of heat exchanger and discharged to the outside.

- Dehumidified air goes through heater and exchanges heat with high-temperature compressed air in the dryer, leading to increase in temperature and decrease in relative humidity.

- Then, remaining moisture is removed from rear filter and high-quality of dry compressed air is supplied to the outside.